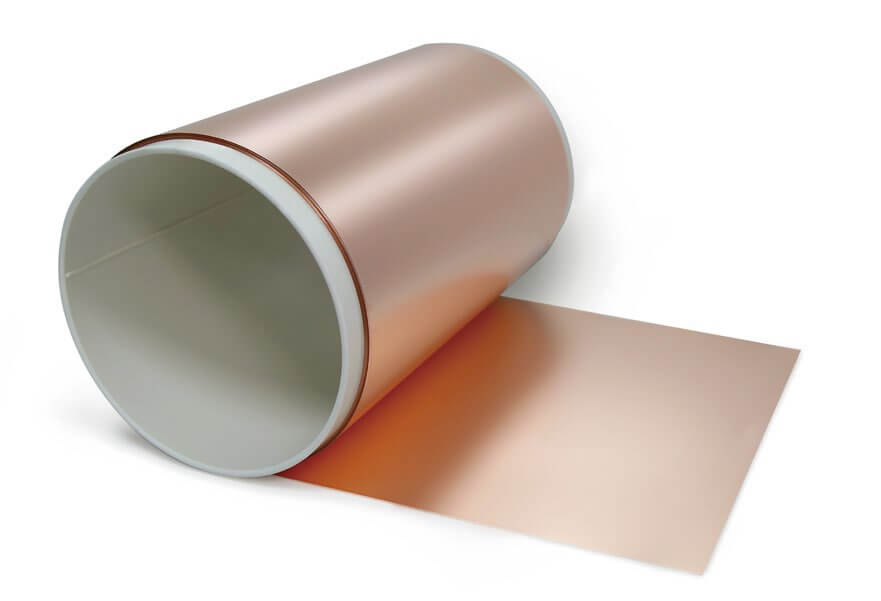

The flexible copper clad substrate (FCCL) is composed of three materials: copper foil, adhesive and PI film through high-precision coating technology. It has the characteristics of high temperature resistance, high insulation and high deflection. Widely used in FPC manufacturing.

It has the characteristics of high temperature resistance, high insulation and high deflection. Widely used in FPC manufacturing.

The flexible copper clad substrate (FCCL) is composed of three materials: copper foil, adhesive and PI film through high-precision coating technology.

It has the characteristics of high temperature resistance, high insulation and high deflection. Widely used in FPC manufacturing.

The flexible copper clad substrate (FCCL) is composed of three materials: copper foil, adhesive and PI film through high-precision coating technology.

It has the characteristics of high temperature resistance, high insulation and high deflection. Widely used in FPC manufacturing.

The flexible copper clad substrate (FCCL) is composed of three materials: copper foil, adhesive and PI film through high-precision coating technology.

It has the characteristics of high temperature resistance, high insulation and high deflection. Widely used in FPC manufacturing.

The flexible copper clad substrate (FCCL) is composed of three materials: copper foil, adhesive and PI film through high-precision coating technology.

We really look forward to meeting you and getting to know your business!